Products

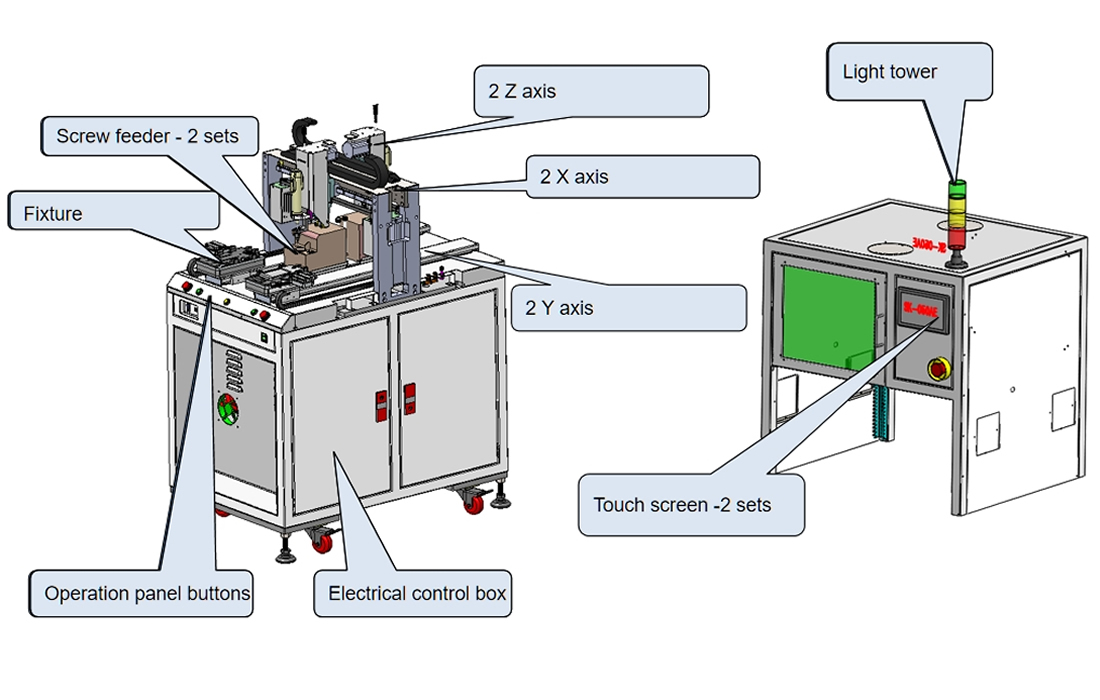

ASD-L206 adopt double X/Y/Z axis system which is suited for one product with 2 kinds of screws, double Y axis design to reduce product exchanging time dramatically improve the production capacity.

Features

● ASD-L206 has double X /Y/Z axis design. it is suited for one product which have 2 kinds of screws.

● The motion system adopt a 6-axis closed-loop stepper motor.

● The control system adopt PLC with touch screen.

● 2 set of electronic screw driver and 2 set of screw feeder for handling 2 different screws.

● High accuracy: repeatability is controlled within ± 0.05mm.

● Lock screw defective rate control within 3‰ (depending on the screw).

● With intelligent detection function, can detect missing driving, floating driving, loose screw driving, etc.

● Applicable to a variety of different shapes of head screws (cross slot, hexagonal, countersunk head, plum, etc.)

Specification

| Model | ASD-L206 |

|---|---|

| Work table size(mm) | 450mm*210mm *2 work table |

| Driving system | Double X/Y/Z axis step motor control |

| Control system | PLC + touch screen |

| Screw range | M1-M5 |

| Screw picking method | vaccum picking |

| Screw driving speed | 1.0- 2.2 seconds /pcs |

| Positioning Repeatability | ±0.05mm |

| Compressed air pressure requirement | 0.4-0.7Mpa |

| Machine size(mm) | W800mm*D1500mm*H1500mm |

| Power Supply | AC 220V 50 Hz |

| Power | 300W |

Copyright © 2025. 1clicksmt-autoscrewdriving. All Rights Reserved